Hydrogen Production and Storage Model: Advancing the Future of Clean Energy

The Role of Hydrogen Models in Renewable Energy Development

Transforming Hydrogen Infrastructure Planning

The global demand for renewable energy has positioned hydrogen as a key solution for reducing carbon emissions and creating a more sustainable energy grid. Hydrogen is widely used in fuel cells, large-scale energy storage, and industrial applications, making the development of efficient hydrogen infrastructure models critical for future energy systems.

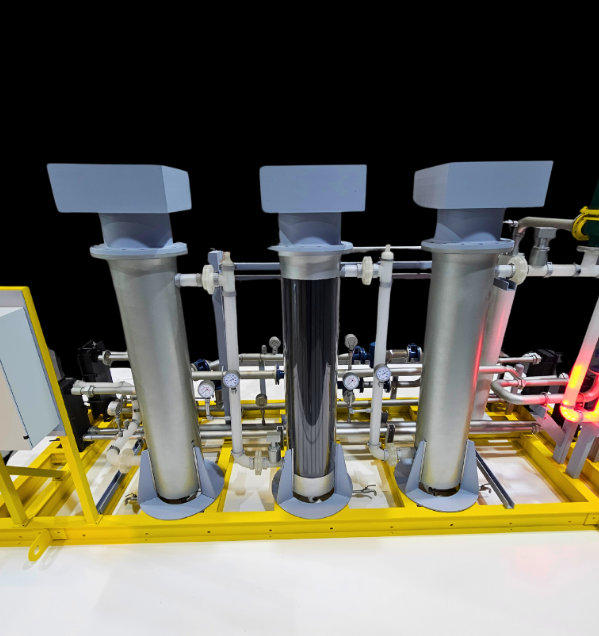

At ARI Model, we develop hydrogen production and storage models that provide engineers and decision-makers with a tangible representation of energy systems. These models allow for testing configurations, optimizing storage facilities, and enhancing hydrogen distribution networks before full-scale implementation.

A physical model of a hydrogen facility provides invaluable insight for stakeholders, making it easier to visualize complex processes, identify inefficiencies, and improve energy management strategies. In addition, these models serve as powerful communication tools, helping to educate the public, attract investors, and support policy development for a clean energy transition.

? Learn more about hydrogen infrastructure models at ARI Model

Key Benefits of Hydrogen Production and Storage Models

Optimizing Hydrogen Refining and Storage Facilities

The production and storage of hydrogen involve complex processes and technologies, including electrolysis, fuel cells, and high-pressure storage tanks. A physical hydrogen infrastructure model provides:

-

A realistic representation of hydrogen production operations, allowing engineers to enhance efficiency and safety.

-

A platform for integrating renewable energy sources, such as wind and solar-powered electrolysis, ensuring sustainable hydrogen production.

-

A practical planning tool for urban developers and policymakers, enabling the integration of hydrogen storage solutions into smart cities and energy grids.

Advancing Hydrogen Energy Research and Development

The hydrogen economy relies on continuous innovation. ARI Model supports research institutions, universities, and energy companies by providing detailed scale models that enable:

-

Prototype testing to identify potential design flaws before full-scale implementation.

-

Enhanced training for engineers and energy specialists, allowing hands-on learning about hydrogen infrastructure.

-

Collaboration between academia and industry, supporting the development of next-generation hydrogen technologies.

Enhancing Investor Confidence and Stakeholder Engagement

Hydrogen infrastructure projects require substantial investment and regulatory approval. A well-crafted hydrogen model provides:

-

A clear, visual representation of the project's economic potential, helping investors make informed decisions.

-

An effective way to demonstrate how hydrogen integrates into existing energy networks, increasing stakeholder confidence.

-

A communication tool for government agencies and policymakers, ensuring smoother approval processes and regulatory compliance.

? Learn more about hydrogen fuel on Wikipedia

Cutting-Edge Technologies in Hydrogen Model Manufacturing

3D Printing for High-Precision Components

3D printing has transformed hydrogen model-making, allowing for the creation of:

-

Miniaturized electrolysis systems and fuel cells, accurately replicating real-world hydrogen plants.

-

Complex hydrogen pipeline networks, ensuring efficient planning of distribution infrastructure.

-

Custom hydrogen storage tanks and pressure vessels, designed for industrial applications.

CNC Machining for Structural Integrity

CNC machining plays a critical role in building durable and structurally stable hydrogen models. At ARI Model, we use CNC milling and routing to:

-

Ensure the longevity of hydrogen facility models used for research and education.

-

Develop precise framework designs for hydrogen storage plants and refueling stations.

-

Integrate modular hydrogen storage components for large-scale clean energy projects.

Laser Cutting for Precision Detailing

Laser cutting is essential for fine detailing in hydrogen model-making, allowing for:

-

Highly accurate cuts that match real-world hydrogen infrastructure blueprints.

-

Engraved safety markings and technical labeling for educational and industrial applications.

-

Fine-textured surface detailing, enhancing the realism of hydrogen production models.